Techniques for Repointing Cavity Walls

The Repointing Process

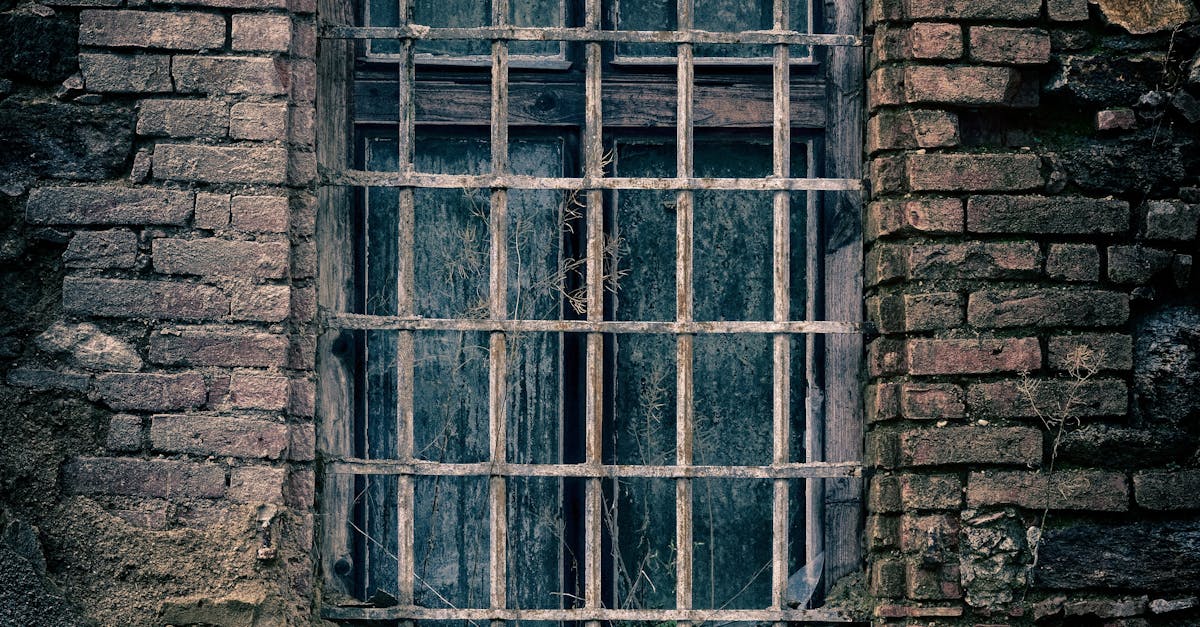

Repointing involves the removal of deteriorated mortar from the joints of brick or stone walls, followed by the application of new mortar to restore structural integrity and aesthetic appeal. Proper assessment of the existing mortar is critical in determining the extent of damage and the best approach for removal. Tools such as chisels, grinders, and oscillating multi-tools may be used to carefully extract old mortar without causing harm to the surrounding brickwork.

Once the old mortar is removed, cleaning the joints thoroughly is essential. This ensures optimal adhesion of the new mortar. The mix for the new mortar should match the original in terms of composition and colour, maintaining the building's character. Application techniques require attention to detail, ensuring that the mortar fills the joint adequately and is compacted to prevent future erosion. The blending of colours and textures may also be considered to achieve a seamless appearance.

A StepbyStep Guide to Repointing

Begin by preparing the area around the wall. Clear away any debris or loose mortar using a chisel and a wire brush. Take care to avoid damaging the surrounding bricks. If any bricks are cracked or damaged, consider replacing them before you start. Proper preparation ensures that the new mortar adheres adequately and leads to a better finish.

Next, mix your mortar according to the manufacturer's instructions. A well-mixed mortar will provide the necessary strength and durability. Use a pointing trowel to apply the mortar into the joints, ensuring to fill them completely. Compact the mortar firmly to prevent air pockets, which can lead to a weaker joint. After filling the joints, smooth the surface using a jointing tool for a neat appearance.

Tools and Techniques for Effective Repointing

Selecting the right tools is essential for achieving a successful repointing job. Trowels, chisels, and jointing tools are the primary instruments required for removing old mortar and applying new. A pointing trowel is particularly useful for precise mortar application, while a toothed scraper can help clean up the joints effectively. A vacuum or brush will assist in removing debris from the joints, ensuring that the new mortar adheres well to the brickwork. Using a mortar mixer can also improve the consistency of the mix, making it easier to work with.

Techniques play a crucial role in ensuring effective repointing. A common practice is to remove the existing mortar to a depth of at least 20 to 30 millimetres before applying the new mix. This depth promotes better adhesion and durability. When applying mortar, it is essential to pack it firmly into the joints without leaving air pockets. Creating a slight concave joint can also help shed rainwater, preventing moisture from penetrating the wall structure. Maintaining a consistent temperature during the application process is vital, as extreme conditions can adversely affect the curing of the mortar.

Best Practices for Mortar Application

Choosing the right type of mortar is essential for ensuring a successful repointing job. The mortar composition should closely match that of the existing brickwork. A softer lime-based mortar is often recommended for older buildings due to its flexibility and breathability. This consideration helps prevent damage to the bricks and allows for the natural movement of the structure, which is crucial in fluctuating weather conditions.

Applying the mortar effectively is equally important. Mortar should be packed firmly into the joints to eliminate gaps and voids, ensuring a strong bond with the bricks. It is advisable to use a pointing trowel or a similar tool to fill the joints neatly and maximise adhesion. Avoid overworking the mortar, as excessive manipulation can lead to weakened joints. After application, the mortar should be finished with a damp sponge to create a clean and uniform appearance.

Curing and Finishing Techniques

After the repointing process, allowing the new mortar to cure properly is critical for durability and effectiveness. The curing time can vary depending on the type of mortar used and environmental conditions. It is generally advised to keep the mortar damp for at least 48 hours following application. This can be achieved by misting the area with water or using wet hessian to cover the joints. A consistent moisture level helps prevent cracking and shrinking while the mortar sets.

Finishing touches can enhance both the aesthetic and functional aspects of the repointed walls. Once the mortar has reached an adequate hardness, any excess can be cleaned off to ensure a neat appearance. If required, a brush can be used to create a textured finish that matches the original wall. Additionally, applying a sealant can provide added protection against moisture infiltration, leading to improved longevity for the structure. Careful attention to these final steps contributes significantly to the overall success of the repointing project.

Ensuring Longevity of Repointed Walls

Proper curing of the mortar is crucial for its durability. After application, it is essential to keep the mortar damp to prevent rapid drying. This can be achieved by misting the newly pointed areas with water regularly. Additionally, covering the repointed sections with a protective tarp or sheets can shield them from harsh weather conditions. Such measures significantly reduce the risks of cracks and deterioration over time.

Regular maintenance of the repointed walls also contributes to their longevity. Homeowners should inspect the mortar joints periodically for any signs of wear or damage. Addressing small issues promptly can help prevent more extensive restoration in the future. Furthermore, ensuring that gutters and drainage systems are functioning properly will minimise moisture exposure to the masonry. These proactive steps help in preserving the integrity of repointed walls for years to come.

FAQS

What is repointing and why is it necessary for cavity walls?

Repointing is the process of renewing the external pointing of masonry walls, which involves replacing deteriorated mortar joints. It is necessary for cavity walls to maintain structural integrity, prevent moisture ingress, and prolong the lifespan of the walls.

How often should cavity walls be repointed?

The frequency of repointing depends on several factors, including the quality of the original mortar, environmental conditions, and exposure to moisture. Generally, it is recommended to assess the condition of the mortar every 10 to 20 years.

What tools are needed for repointing cavity walls?

Essential tools for repointing include a pointing trowel, mortar mixer, chisel, joint rake, and a brush. Safety equipment like gloves and goggles should also be used during the process.

Can I repoint cavity walls myself, or should I hire a professional?

While it is possible to repoint cavity walls yourself if you have the necessary skills and tools, hiring a professional is often advisable for larger projects or if you are unsure about the techniques involved. This ensures the work is done correctly and safely.

What type of mortar is best for repointing cavity walls?

The best type of mortar for repointing depends on the existing mortar and the type of masonry. Generally, a lime-based mortar is preferred for older buildings, as it allows for flexibility and breathability, while a cement-based mortar may be suitable for newer constructions.

Related Links

Solutions for Bulging Cavity WallsRestoring Structural Integrity of Cavity Walls

Evaluating Cost-Effective Repairs for Cavity Walls

Repairing Cavity Wall Ties

Fixing Water Ingress in Cavity Walls

Replacing Damaged Insulation in Cavity Walls

Addressing Dampness in Cavity Walls

Repairing Cracks in Cavity Walls